Alright, let's talk about the unsung hero of your machining setup: the Stud Kleen. You might know it as a pull stud, a retention knob, or maybe just "that threaded thingamajig that holds the tool." Whatever you call it, this little guy is way more important than it looks. It's the handshake between your expensive machine and your cutting tool, and if that handshake is weak, things can get ugly, fast. This article is all about giving the stud kleen the attention it deserves, from how to put it in right to knowing when it's time to let it go. Let's talk shop.

Key Takeaways

- Treat your stud kleen with care; it's not just a simple bolt. Proper installation and regular checks prevent big issues.

- Using a torque wrench is key when putting in a stud kleen. Over-tightening or using the wrong methods can damage your equipment.

- Stud kleens don't last forever. Keep track of their hours or replace them every few years to avoid unexpected failures.

- Regularly check your stud kleen for any dents, cracks, or wear. It's a small part of maintenance that can save a lot of trouble.

- When picking a new stud kleen, think about the materials and how it's made, not just the price. A good fit means better performance and less wear.

The Stud Kleen's Existential Crisis: Why It Matters

The 'Ignore It' Strategy: A Recipe For Disaster

Look, we all get busy. Sometimes, things just… keep running. You know, until they don't. The Stud Kleen, that unsung hero of your tooling setup, often falls into this category. It's not exactly glamorous, is it? It's not the shiny new machine or the fancy software. It's just… there. And because it's just 'there,' it's easy to forget it exists. This 'out of sight, out of mind' approach is, frankly, a terrible plan. It’s like ignoring that weird rattle in your car. Sure, it might be fine for a while, but eventually, that little noise is going to turn into a full-blown breakdown, probably at the worst possible moment. Ignoring your Stud Kleen is basically inviting a mechanical meltdown.

Why Your Stud Kleen Deserves a Spa Day

Think about it. Your Stud Kleen is the little guy holding onto your cutting tools for dear life. It's taking a beating, day in and day out. It’s constantly being tightened, loosened, and subjected to all sorts of forces. It deserves a little TLC, not to be treated like a disposable coffee cup. Giving it a bit of attention – a quick clean, a check for damage – is like sending it to a spa. It comes back refreshed, ready to do its job properly, and less likely to throw a tantrum.

Here’s why that spa day is so important:

- It prevents unexpected downtime: A Stud Kleen failure isn't just a small hiccup; it can stop your entire operation. That's lost time and lost money.

- It protects your other equipment: A failing Stud Kleen can damage your spindle or tool holder. Those are expensive repairs.

- It ensures accuracy: A worn or damaged Stud Kleen can lead to tool runout, messing up your precision work.

When a Stud Kleen fails, it's rarely a quiet, dignified exit. It's more of a spectacular, noisy implosion that brings everything to a screeching halt. Don't let your Stud Kleen become a cautionary tale whispered in hushed tones around the breakroom.

The 'Thingamajig' That Holds It All Together

Okay, maybe 'thingamajig' isn't the technical term, but you get the idea. The Stud Kleen is the critical link. It's the part that interfaces with your tool holder and your spindle. If this connection is compromised – due to wear, damage, or just being the wrong fit – everything else starts to go wrong. It’s like trying to build a house on a shaky foundation. Eventually, the whole structure is going to suffer. This small component is surprisingly vital for the overall health and performance of your machining setup.

Grease Is The Word: Keeping Your Stud Kleen Happy

Okay, let's talk about the unglamorous but totally necessary world of Stud Kleen lubrication. You might think of your Stud Kleen as just a tough piece of metal, but it's actually working pretty hard in there. Spinning around, holding tools that are doing all the heavy lifting (or cutting, in this case). If you just ignore it, well, things can get sticky. And not in the good, "we're making progress" kind of way.

A Little Lube Goes A Long Way

Think of lubrication as giving your Stud Kleen a tiny, but vital, spa treatment. A bit of grease applied regularly can make a world of difference. It's not about drowning it; just a light coating is usually enough. This simple act helps everything move smoothly and reduces that nasty friction that wears parts down faster than you can say "tool change."

The Importance Of Regular Lubrication

So, how often should you be slathering on the grease? For most standard operations, a monthly check and re-lube should do the trick. However, if you're running through-spindle coolant, that stuff can wash away lubricants pretty quickly. In those cases, you might want to bump it up to a weekly routine. It's like giving your car an oil change – a small task that prevents major breakdowns later on. Keeping things properly greased is your first line of defense against a whole heap of problems.

Preventing Bearing Failures And Tooling Woes

What happens when you skip the lube? Friction, my friends. Lots of it. This friction is the enemy of bearings, leading to premature wear and eventual failure. When a bearing goes kaput, it's not just the Stud Kleen that suffers. It can mess with your tooling, leading to poor cut quality, tool breakage, and even damage to your machine spindle. It's a domino effect of expensive problems.

Here's a quick rundown of why regular lubrication is your best buddy:

- Reduces Friction: Less rubbing means less heat and less wear.

- Prevents Corrosion: Grease acts as a barrier, keeping moisture and contaminants away from sensitive parts.

- Improves Movement: It helps the Stud Kleen and associated parts slide and engage smoothly.

- Extends Lifespan: Simply put, a well-lubricated Stud Kleen lasts longer.

Don't underestimate the power of a simple grease gun. It's a small investment of time that pays off big in preventing costly repairs and downtime. Think of it as preventative medicine for your machinery.

Inspection Station: Dents, Dings, And Despair

Before You Even Think About Installing

Alright, let's talk about that little guy, the Stud Kleen. Before you even think about shoving it into your spindle, give it a good once-over. Seriously, don't just grab it and go. It’s like checking your car tires before a long trip; you don’t want a blowout when you’re miles from anywhere. Look for any gnarly dents, tiny cracks that look like they're plotting something sinister, or corrosion that makes it resemble something dug up from an ancient tomb. If you spot any of these battle scars, it's probably time to let that Stud Kleen retire. A quick visual check now can save you a massive headache, and a whole lot of cash, later on.

Spotting Battle Scars On Your Stud Kleen

Ever peeked into that overflowing drawer in the corner of the shop? The one where all the old, beat-up Stud Kleens go to mingle? It's a chaotic mess, a metal mosh pit where every ding and scratch is a potential future failure. This isn't just about shop organization; it's about the integrity of your tools. When you've got a jumble of different brands and types, it's way too easy to grab the wrong one. Using a Stud Kleen that isn't quite right is like trying to use a butter knife to cut steak – it's not going to end well, and you'll probably just make a mess. Here's what happens in the Drawer of Doom:

- Physical Damage: Each impact adds microscopic cracks, weakening the stud. Think of it as a tiny paper cut that gets infected.

- Corrosion: Moisture and grime build up, leading to rust and reduced grip. Nobody likes a rusty handshake, especially not your spindle.

- Mix-ups: Grabbing the wrong size or type can damage the toolholder or spindle. This is where things get really expensive.

This chaotic storage method is a breeding ground for problems. It's not just unsightly; it actively contributes to premature wear and potential catastrophic failure down the line. A little bit of order can go a long way.

Retire That Stud Kleen Before It's Too Late

Let's be honest, the Stud Kleen isn't exactly the star of the show in your machining setup. It's more like the quiet, unassuming stagehand who makes sure the whole production doesn't fall apart. But just because it's not flashy doesn't mean it doesn't have its own set of anxieties. Think of it as having a mini identity crisis every time it gets shoved into a spindle. Is it just a glorified bolt? Or is it the linchpin holding your entire operation together? The truth is, it's both, and treating it like it's just "there" can lead to some serious drama. If your Stud Kleen is showing signs of wear, it might be time to consider some professional repair solutions, like those offered by KECO's advanced Glue Pull Repair systems. Sometimes, a little professional attention can bring a tool back from the brink.

The 'Mix And Match' Approach: A Cavalcade Of Chaos

You know that drawer? The one overflowing with Stud Kleens, all jumbled together like they’re at a chaotic metal concert? Yeah, that’s the ‘Drawer of Doom,’ and it’s a prime example of the ‘mix and match’ approach gone wild. It’s not just an eyesore; it’s a ticking time bomb for your equipment.

The Mosh Pit Of Stud Kleens

Think about it. Every Stud Kleen in that drawer has probably bumped into its neighbors more times than a teenager at a school dance. These little collisions might seem harmless, but they can create tiny nicks and scratches. These aren't just cosmetic flaws; they're potential weak spots. When you grab one of these battered veterans for a job, you're not just using a tool; you're introducing a gamble into your operation. It’s like trying to build a house with slightly warped lumber – it might stand, but it’s not going to be as solid as it should be.

Why Mixing Stud Kleens Is A Gamble

Beyond the physical damage, there’s the issue of compatibility. Shops often end up with a motley crew of Stud Kleens from different manufacturers, or even different batches of the same brand. They might look similar, but their tolerances can be just different enough to cause problems. Using a Stud Kleen that isn't a perfect match for your spindle or tooling is asking for trouble. It can lead to uneven pressure distribution, causing vibrations that shake things up more than they should. This constant jostling wears down not just the Stud Kleen itself, but also the more expensive parts it interacts with, like your spindle bearings.

The Costly Consequences Of Wrong Fits

So, what happens when you throw a mismatched Stud Kleen into the mix? It’s rarely a good outcome. You might experience:

- Premature Wear: The Stud Kleen, your tooling, and even the spindle itself will wear out faster than they should.

- Vibration Issues: Unwanted shaking can affect the quality of your work and lead to fatigue in other components.

- Sudden Failures: A Stud Kleen that’s under stress from a poor fit is more likely to break unexpectedly, potentially causing significant damage.

- Increased Downtime: Dealing with the fallout from a bad fit means stopping your work to fix or replace parts, costing you time and money.

It’s easy to think of a Stud Kleen as just another piece of hardware, but its role is surprisingly precise. When you start mixing and matching, you’re essentially throwing a wrench into a finely tuned system. The goal is always a snug, consistent fit, and anything less is just asking for a headache down the road.

Don't let your Stud Kleens live in a chaotic mosh pit. Keep them organized, inspect them regularly, and always use the right one for the job. Your wallet, and your machinery, will thank you.

Marking Your Territory: Date Codes And Serial Numbers

Flying Blind With Your Stud Kleen

Ever stare at a Stud Kleen and just… guess? Yeah, me neither. Okay, maybe sometimes. But seriously, if you don't know how old your Stud Kleen is or where it came from, you're basically operating in the dark. It's like trying to bake a cake without a recipe – you might get lucky, but chances are it's going to be a disaster. Without any identifying marks, you've got no idea if it's been through the wringer or if it's practically fresh out of the box. This makes planning replacements a total shot in the dark.

Etching Your Stud Kleen's Age

Some of the fancier Stud Kleens come with date codes and serial numbers already etched right onto them. Pretty neat, huh? If yours are bare-bones, though, don't sweat it. You can get them professionally laser-marked, or if you're feeling a bit DIY, a good permanent marker can do the trick in a pinch. It’s not exactly brain surgery, but it’s a solid way to keep tabs on their age. Think of it as giving your Stud Kleen a birth certificate.

- Get it marked: Whether it's professional etching or a trusty marker, make sure there's something to identify it.

- Keep a log: Jot down the date you put it into service. Easy peasy.

- Check the manufacturer: Sometimes, you can find information using the manufacturer part number.

Knowing When It's Time For A Replacement

So, you've got these marks. Now what? Well, these little bits of info are your golden ticket to knowing when it's time to say goodbye. They help you track usage and age, which is super important because, let's face it, metal gets tired. It doesn't matter if it's been working 40 hours a week or 168 hours a week; time and stress take their toll. Knowing the history of your Stud Kleen means you can swap it out before it decides to call it quits mid-operation, saving you a massive headache and a potentially costly repair.

Ignoring the age and history of your Stud Kleens is a gamble. You're betting on them holding up, and the house (your machine) always wins when they fail.

The Three-Year Itch: A Stud Kleen Replacement Strategy

Look, nobody likes thinking about replacing parts. It’s like admitting your favorite pair of jeans has finally given up the ghost. But here’s the deal: your Stud Kleen isn't immortal. Even if it’s been chugging along without a hitch, time itself is a sneaky saboteur. Metal fatigue doesn't check your maintenance logs; it just happens.

Metal Fatigue Doesn't Care About Hours

Think of your Stud Kleen like a trusty old soldier. It's seen action, it's done its job, but eventually, even the toughest metal gets tired. Those tiny stresses from constant clamping and unclamping add up. It’s not always about the total hours logged; it’s about the quality of those hours and the sheer passage of time. Ignoring this is like ignoring a weird noise your car is making – it’s probably going to get louder and more expensive.

Standard Shifts vs. 24/7 Operations

So, when do you actually pull the trigger on a replacement? It really depends on how hard you're riding your Stud Kleens. If your shop operates on a more standard schedule, say, a typical eight-hour shift, aiming for a replacement every three years is a pretty solid plan. It gives you a good buffer. But if your machines are running around the clock, like a non-stop party, you’ll want to shorten that interval. For those 24/7 operations, looking at an annual replacement might save you from a major breakdown.

Here’s a rough guide:

- Standard Shifts (approx. 8 hours/day): Consider replacement every 3 years.

- Extended Shifts (approx. 12-16 hours/day): Consider replacement every 1.5 - 2 years.

- 24/7 Operations: Consider replacement annually.

Proactive Replacement Saves Headaches

This whole replacement thing is really about being smart and avoiding those

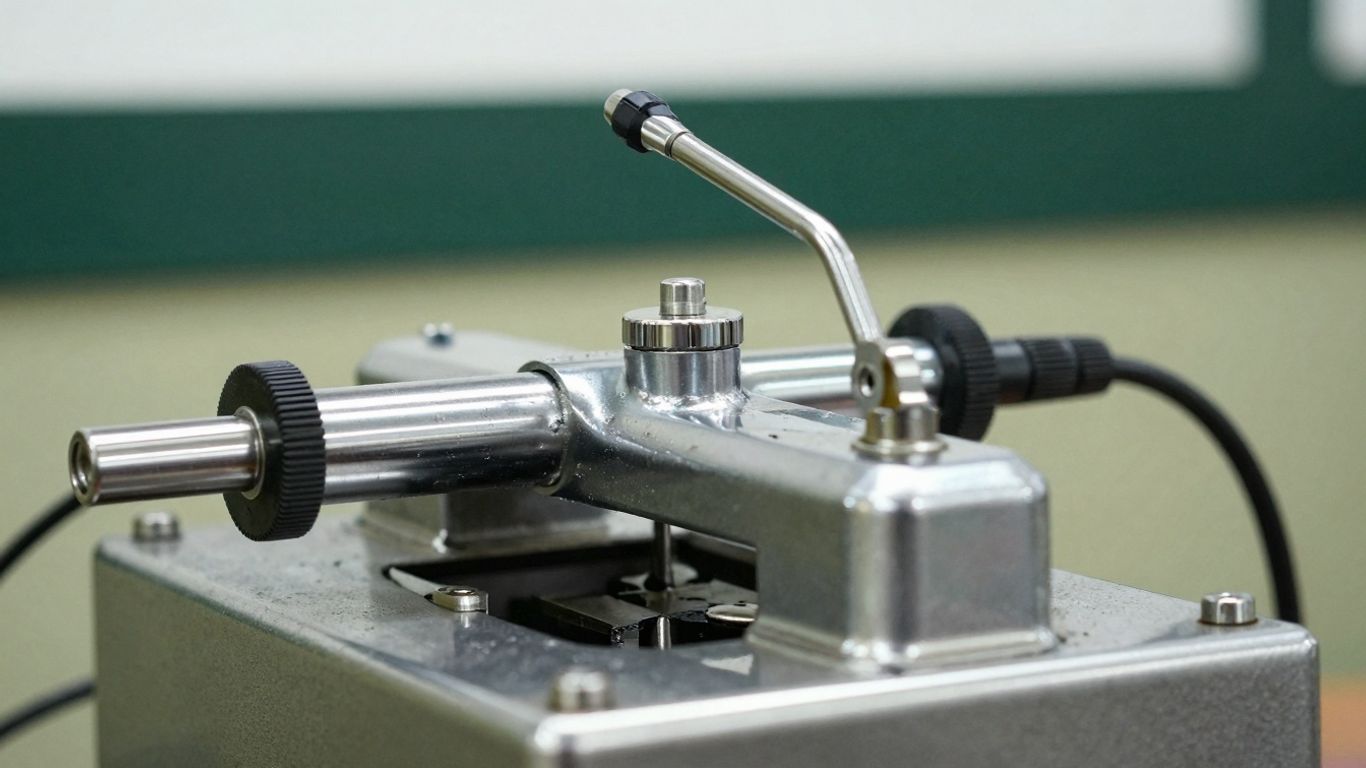

The Cylindrical Pilot: A Perfect Fit For Your Spindle

The Bit That Really Matters

Alright, let's talk about the part of your Stud Kleen that actually does the heavy lifting, or rather, the smooth sliding. It's the cylindrical pilot. This isn't just some random bit of metal sticking out; it's the precision-ground end that slides into your toolholder. Think of it like trying to shove a square peg into a round hole – if that pilot isn't perfectly round and smooth, things are going to get ugly. A sloppy fit here means your whole setup can get a little… jiggly. And nobody wants a jiggly tool holder, right?

A Bent Key In A Lock Analogy

Imagine you've got a fancy lock on your front door. Now, what if the key you were using was slightly bent? It might go in, sure, but it wouldn't turn smoothly. You'd have to wiggle it, force it, and you'd probably end up scratching up the lock and the key. That's exactly what happens when your Stud Kleen's pilot isn't up to snuff. It forces its way into the toolholder, causing stress and wear. A perfectly ground pilot ensures a snug, flush fit, which is key to keeping everything balanced and running true. It's the difference between a smooth, quiet operation and a noisy, vibrating mess that’s begging to break.

Preventing Vibrations Before They Start

So, why is this pilot so important for vibration? It all comes down to balance. When the Stud Kleen sits perfectly flush in the toolholder, thanks to that nice, round pilot, the weight is distributed evenly. It's like making sure all the tires on your car are the same size and properly inflated. If one Stud Kleen is a bit off, or its pilot is damaged, it creates an imbalance. This imbalance is what leads to those annoying vibrations. They don't just sound bad; they can actually damage your spindle bearings, wear out your tooling faster, and generally make your life miserable. A good pilot is your first line of defense against this mechanical mayhem.

Here’s what to look for in a good pilot:

- Smoothness: It should feel like polished glass, not sandpaper.

- Roundness: It needs to be perfectly cylindrical, no flat spots allowed.

- Cleanliness: Free from any nicks, dings, or rust that could affect the fit.

Don't skimp on this detail. A few extra minutes checking the pilot, or choosing a Stud Kleen with a better finish, can save you hours of troubleshooting and costly repairs down the line. It's the small things that make the biggest difference in the long run.

The Cylindrical Pilot is designed to be a perfect fit for your spindle, making your work easier and more efficient. It's a simple yet effective tool that helps you get the job done right. Want to see how it can help you? Visit our website to learn more and order yours today!

So, What's the Takeaway?

Look, nobody's saying you need to throw a birthday party for your Stud Kleens, but a little bit of attention goes a long way. Ignoring them is basically asking for trouble, and trust me, trouble in the shop usually means a big, fat, expensive mess. So, give 'em a little grease, check for dents, and maybe, just maybe, think about replacing them before they decide to retire in a spectacular, machine-halting fashion. It’s not rocket science, but it’s way better than explaining to your boss why the whole operation is down because a tiny metal thingamajig decided to call it quits. Keep 'em clean, keep 'em happy, and they'll keep your tools doing their thing without a fuss. Easy peasy.

Frequently Asked Questions

What is a Stud Kleen and why is it so important?

Think of a Stud Kleen as a small but really important metal piece that connects your machine's spindle to the cutting tool. It's like a strong handshake that keeps everything steady. If this connection is weak or damaged, it can cause big problems, like ruining your tools or even damaging your machine.

What happens if I put in a Stud Kleen the wrong way?

Putting in a Stud Kleen incorrectly can be a huge mistake. Using too much force, like hitting it with a hammer or using a super long wrench, can break the Stud Kleen or damage the machine. It might also make the metal swell, leading to a loose fit, shaky operations, and faster wear. Always use the right tools and follow the instructions!

How often should I check or replace my Stud Kleen?

You should regularly look for any dents, cracks, or rust on your Stud Kleen. It's also a smart idea to have a plan for when to swap them out. A good rule of thumb is to replace them about every three years, or even more often if you use your machine a lot. Don't wait until it breaks!

Does the material and coating of a Stud Kleen really make a difference?

Yes, it absolutely does! Using good quality steel makes a Stud Kleen tougher and helps it last longer. Special coatings, like black oxide, help prevent rust. Also, look for Stud Kleens where the important parts are precisely ground after they're hardened. This makes sure they fit perfectly and run smoothly, which means less wobbling and shaking.

What is 'fretting' and why is it bad for my Stud Kleen?

Fretting is a type of wear that happens when two metal surfaces rub against each other, often because of vibrations. If your Stud Kleen isn't fitted just right or is a bit loose, it can vibrate. This rubbing action wears away the metal, which can damage your tool holder and spindle over time. It's like having tiny bits of sandpaper constantly rubbing.

Is it okay to mix and match Stud Kleens from different brands?

Mixing Stud Kleens from different companies or ones that have been used differently is a risky move. They aren't all made the same, and using the wrong one can cause uneven pressure, shaking, and parts breaking too soon. It's best to stick with the correct type for your machine to avoid costly repairs.